Hi Folks!

I'll be starting my vegetable seeds for the garden in a few weeks, so I pulled my nursery out of mothballs (and by "mothballs" I mean dust and cobwebs).

My nursery is just a metal rack that I've repurposed by adding some casters, shelves, and a couple of light fixtures made of scrap lumber. Since the lights are most effective when they're just a few inches above the baby plants, I've tried several ways of making them adjustable so I can raise them as the plants grow. The goal has been to come up something that would hold the lights securely in position, but that I could easily raise and lower. I came up with a hack using Maker Pipe T-connectors and a few other bits of hardware that probably has a lot of applications.

By spring loading the T-connectors, I can relieve the tension on them, adjust their position, and then release the springs to hold the connectors in place.

Here's what I did:

1.) First, I attached vertical pieces of EMT to either side of the nursery using 3/4" Conduit and Pipe Hangers (available at Home Depot: https://www.homedepot.com/p/Superstrut-3-4-in-Conduit-and-Pipe-Hanger-3-Pack-6H1-TB-8/300325780).

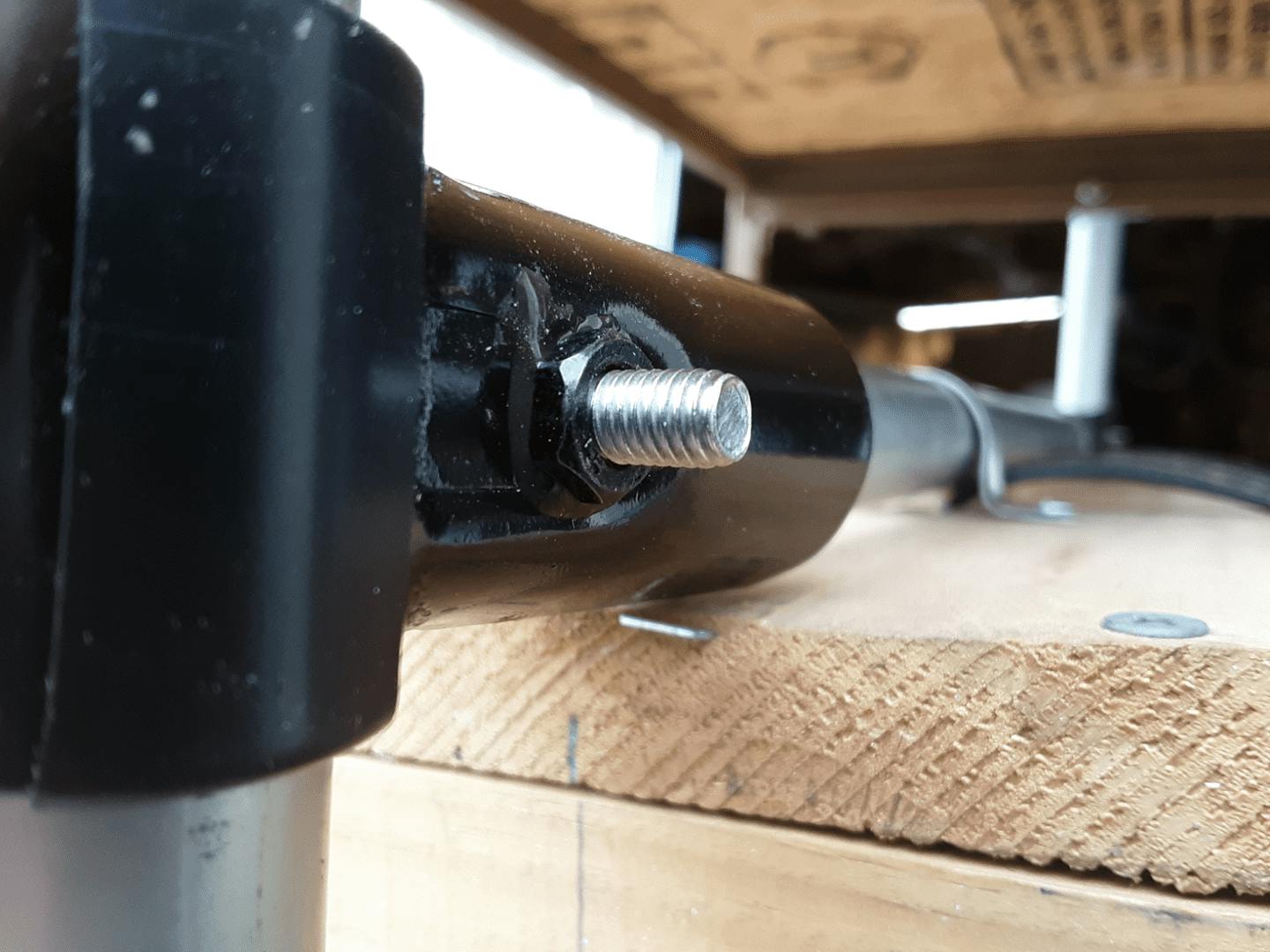

2.) The next thing I did was to cement the nuts to the back side halves of the T-connectors using JB Weld. I had to be very careful here not to get any epoxy on the threads. One of the nuts didn't hold the first time, so I scored the finish around the hole and on the nut with a sharp blade to create a little tooth for the epoxy.

3.) I then replaced the standard M6x1.0x25mm long screws provided by Maker Pipe with some longer (50mm) screws. I used cheese head screws, but pan head screws would probably work just as well.

4.) Once the epoxy was well set, I assembled the connectors, inserting each screw through a spring before running it through the connector. I tightened each screw by hand, then gave it a few turns with a screwdriver, loading the spring just enough to hold the connector tight on the vertical piece of EMT.

The connector isn't tight enough on the horizontal pieces (attached to the light fixtures with 3/4" 2-hole pipe hanger straps from Home Depot: https://www.homedepot.com/p/Oatey-3-4-in-Galvanized-2-Hole-Pipe-Hanger-Strap-10-Pack-33543/303434704?NCNI-5) to prevent all movement (they can rotate and shift axially), but all I need is to keep them suspended.

I tried three different springs. I initially decided on one with less tension because it operated a little more smoothly, but I ended up switching to a stiffer spring because it held the lights more securely. I got the springs from Zoro (https://www.zoro.com/zoro-select-compress-spring-1316x0045-in-pk5-1ncb1/i/G2926926/?q=1ncb1).

David from Maker Pipe recommended Zoro to me and they have become one of my go-to sites for all sorts of hard-to-find hardware items.

I'd be interested to know if anyone else uses this hack and what they use it for. I'm always looking for new ways to do stuff.

#MakerPipeBOTM