Inspired by Mario I. Arguello and his die-compressed bolted conduit solution, I had a similar need but I don’t own an arbor press. I do have a bench vice, but instead of modifying the end of 3/4 EMT, I wanted to see if I could simply flatten a piece of 1/2 EMT enough to fit beyond the constriction point and underneath the bolt hole of a T-connector acting like a piece of bolted rebar. Short answer: Yes, you can. Here’s how:

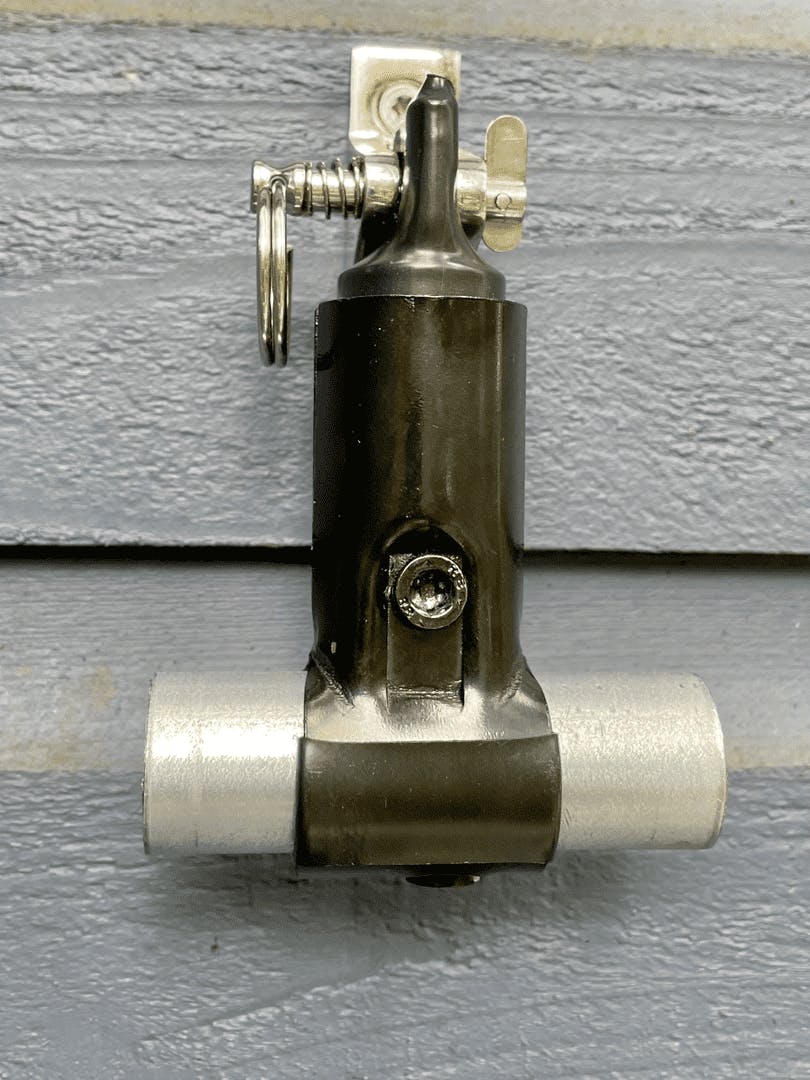

You need to compress the end of 1/2 EMT and drill a hole. The measurements are simple. Position the pipe 3/4" into a vice and start cranking it down. Once you have compressed it to 9/16", you will clear the inner restriction and still manage to slide inside 3/4 EMT. Now, measure 3/8" from the end and mark the spot on center with a nail set. This will be the center of your hole. Drill using a 1/4" bit and make sure the position is centered and does not wander. Drill all the way through both faces of the compressed EMT.

You are left with a pipe that will slip beyond the constriction with a hole that will allow the pipe to be captured by the Maker Pipe bolt. Because Maker Pipe fittings are designed to grab 3/4 EMT, depending on your application, you will need to decide how to “fill” the normal part of the Maker Pipe fitting. You can use the shims available and let the connector grip the 1/2 EMT directly. Or, if you don’t mind the extra weight and want the rigidity of 3/4 you can double up the pipe. It helps to add a couple of friction bands on top of each other around the 1/2 and heat shrink it tight. Slide the 3/4 over the 1/2 and the friction bands inside will help keep the 1/2 centered.

The whole point of this assumes you are making a similar through-hole bolted connection on the other end for a very strong connection that will not slip out. You will need to do some precise measurements to to make this work in your project, as the length of the 1/2 EMT as well as the bolt holes becomes crucial.

I realize it is unusual to double-up the EMT this way if you cannot use just 1/2, but this is fast and simple and provides a secure solution if you need bolted ends without drilling the Maker Pipe fittings and adding more bolts. My specific need was to create a much stronger eye bracket to mate with my bimini hinge. Previously, I had a cast stainless part designed for the purpose, but I did not like that I still needed to attach this to a stub of EMT with the potential for it to pull out of the Maker Pipe under weight. The stainless parts are also expensive, so others could benefit from my insight here and save some money. Making a bolt-secured eye bracket is cheaper and stronger.